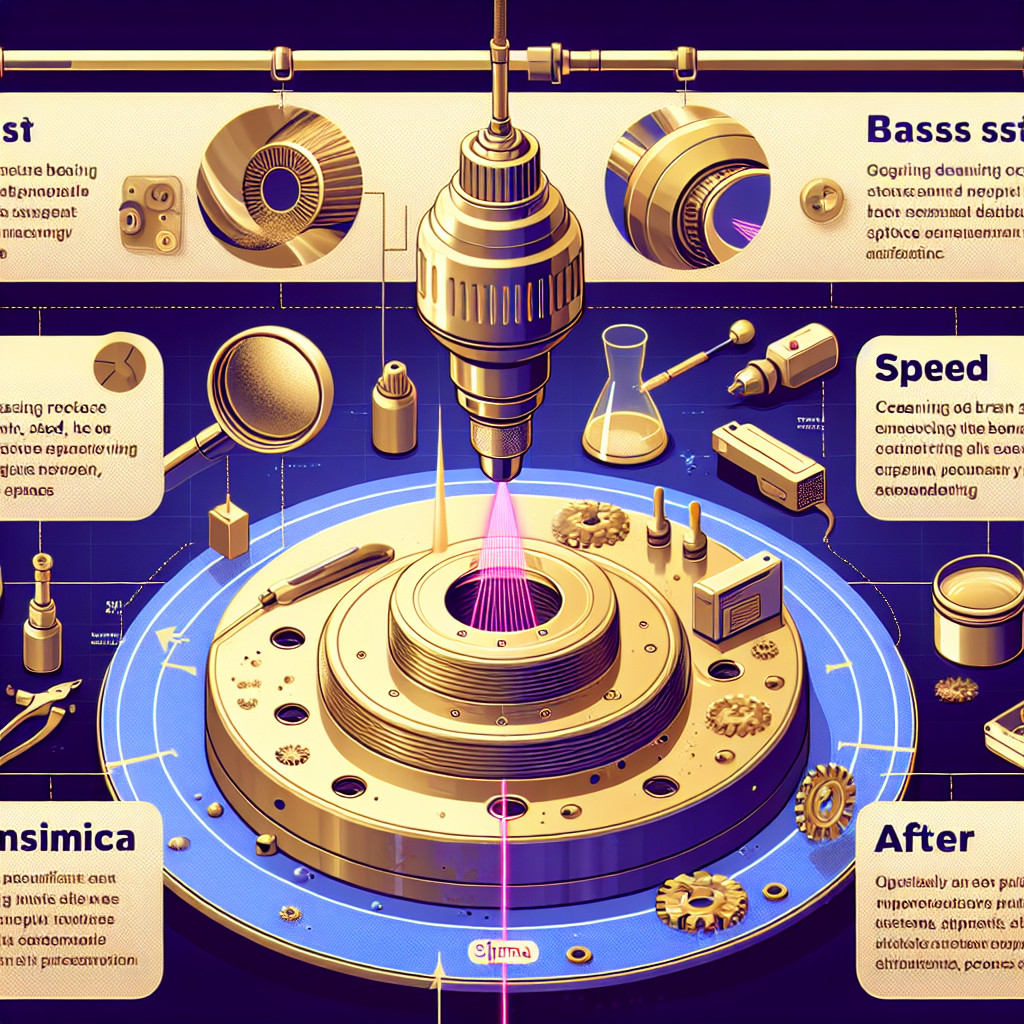

Laser cleaning for removing contaminants from brass surfaces

- Benefits of laser cleaning for brass surfaces

- Comparison of laser cleaning vs traditional cleaning methods for brass

- Effectiveness of laser cleaning in removing contaminants from brass surfaces

- Importance of maintaining clean brass surfaces in various industries

- Case studies showcasing successful laser cleaning of brass surfaces

Benefits of laser cleaning for brass surfaces

Here are some of the key benefits of using laser cleaning for brass surfaces:

1. Non-contact cleaning: Laser cleaning is a non-contact process, meaning that the laser beam does not physically touch the brass surface. This eliminates the risk of scratching or damaging the surface, making it ideal for delicate or intricate brass items.

2. No chemicals or abrasives: Laser cleaning does not require the use of chemicals or abrasive materials, making it an environmentally friendly and sustainable cleaning method. This is particularly important for brass surfaces that may be in contact with food or sensitive materials.

3. Precision cleaning: Laser cleaning allows for precise control over the cleaning process, enabling operators to target specific areas or remove only the desired amount of tarnish or dirt. This level of precision is difficult to achieve with traditional cleaning methods.

4. Efficient and time-saving: Laser cleaning is a fast and efficient process that can remove dirt, tarnish, and other contaminants from brass surfaces in a fraction of the time required by traditional methods. This can result in significant time and cost savings for businesses and individuals.

5. Safe and operator-friendly: Laser cleaning is a safe and operator-friendly process that does not produce harmful fumes or residues. This makes it a suitable cleaning method for indoor environments or areas with strict safety regulations.

6. Long-lasting results: Laser cleaning can provide long-lasting results, with brass surfaces remaining clean and shiny for an extended period of time. This can reduce the frequency of cleaning and maintenance required for brass items.

In conclusion, laser cleaning offers a number of benefits for brass surfaces, including non-contact cleaning, no chemicals or abrasives, precision cleaning, efficiency, safety, and long-lasting results. By choosing laser cleaning for brass surfaces, businesses and individuals can enjoy a modern and effective cleaning method that preserves the beauty and integrity of their brass items.

Comparison of laser cleaning vs traditional cleaning methods for brass

Laser Cleaning

Laser cleaning is a modern and innovative method that uses a high-powered laser beam to remove contaminants from the surface of brass. The laser beam is directed at the brass surface, where it vaporizes the contaminants, leaving behind a clean and shiny surface. Laser cleaning is a non-contact method, which means that there is no physical contact between the cleaning equipment and the brass surface, reducing the risk of damage to the material.

Advantages of Laser Cleaning

- Efficient removal of contaminants

- Non-contact method

- Environmentally friendly

- Precise cleaning

Disadvantages of Laser Cleaning

- High initial cost

- Requires specialized equipment

- May not be suitable for all types of contaminants

Traditional Cleaning Methods

Traditional cleaning methods for brass include using chemical cleaners, abrasive materials, and mechanical tools to remove contaminants from the surface. These methods have been used for many years and are effective in cleaning brass, but they may require more time and effort compared to laser cleaning.

Advantages of Traditional Cleaning Methods

- Cost-effective

- Widely available materials

- Can be used for a variety of contaminants

Disadvantages of Traditional Cleaning Methods

- May require more time and effort

- Physical contact with the brass surface

- May leave residue or scratches on the surface

Comparison

| Aspect | Laser Cleaning | Traditional Cleaning Methods |

|---|---|---|

| Efficiency | High | Effective |

| Cost | High initial cost | Cost-effective |

| Environmental Impact | Environmentally friendly | May use harsh chemicals |

| Precision | Precise cleaning | May leave residue or scratches |

Conclusion

In conclusion, both laser cleaning and traditional cleaning methods have their advantages and disadvantages when it comes to cleaning brass. Laser cleaning is a modern and efficient method that offers precise cleaning without physical contact, but it may require a higher initial cost. Traditional cleaning methods, on the other hand, are cost-effective and widely available, but they may require more time and effort and can leave residue or scratches on the surface. Ultimately, the choice between the two methods will depend on the specific requirements of the cleaning task and the resources available.

Effectiveness of laser cleaning in removing contaminants from brass surfaces

Brass surfaces are commonly used in various industries due to their durability and aesthetic appeal. However, over time, these surfaces can become contaminated with dirt, grease, rust, and other impurities, which can detract from their appearance and functionality. Traditional cleaning methods such as chemical solvents and abrasive scrubbing can be time-consuming, labor-intensive, and potentially damaging to the brass surface.

In recent years, laser cleaning has emerged as a highly effective and efficient method for removing contaminants from brass surfaces. This non-contact, non-abrasive technique uses high-intensity laser beams to vaporize and remove unwanted materials from the surface, leaving behind a clean and pristine finish.

So, what makes laser cleaning so effective in removing contaminants from brass surfaces? Let’s explore some of the key advantages of this innovative cleaning method:

1. Non-contact cleaning: Laser cleaning does not require physical contact with the brass surface, reducing the risk of scratching or damaging the material. This makes it ideal for delicate or intricate brass components that cannot withstand traditional cleaning methods.

2. Precision cleaning: Laser beams can be precisely controlled to target specific areas of the brass surface, allowing for selective removal of contaminants without affecting the underlying material. This level of precision ensures thorough cleaning without compromising the integrity of the brass surface.

3. Efficient removal of contaminants: The high-intensity laser beams used in laser cleaning can quickly and effectively vaporize a wide range of contaminants, including dirt, grease, rust, and paint. This results in a faster and more thorough cleaning process compared to traditional methods.

4. Environmentally friendly: Laser cleaning is a clean and environmentally friendly process that does not require the use of harsh chemicals or solvents. This makes it a sustainable cleaning solution that minimizes the impact on the environment.

5. Cost-effective: While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings can be significant. Laser cleaning is a highly efficient process that requires minimal maintenance and consumables, resulting in lower overall cleaning costs.

Overall, the makes it a valuable tool for industries that rely on clean and pristine brass components. Whether it’s restoring antique brass fixtures or maintaining the appearance of modern brass fittings, laser cleaning offers a fast, efficient, and environmentally friendly solution for keeping brass surfaces looking their best.

Importance of maintaining clean brass surfaces in various industries

Benefits of maintaining clean brass surfaces

There are several benefits to keeping brass surfaces clean in various industries:

| Benefit | Description |

|---|---|

| Prevention of corrosion | By removing dirt, grime, and other contaminants from brass surfaces, the risk of corrosion is significantly reduced. Corrosion can weaken brass components and lead to premature failure. |

| Improved aesthetics | Clean brass surfaces have a shiny and attractive appearance, which can enhance the overall look of products and equipment in industries such as architecture and interior design. |

| Enhanced conductivity | Dirty brass surfaces can hinder the conductivity of electrical components, affecting the performance of devices. Keeping brass surfaces clean ensures optimal conductivity. |

| Extended lifespan | Regular cleaning and maintenance of brass surfaces can prolong the lifespan of brass components, saving time and money on replacements. |

Importance of clean brass surfaces in different industries

Clean brass surfaces are essential in various industries for different reasons:

| Industry | Importance of clean brass surfaces |

|---|---|

| Automotive | Brass components in vehicles need to be clean to ensure optimal performance and safety. Dirty brass surfaces can lead to malfunctions and accidents. |

| Manufacturing | Clean brass surfaces are crucial in manufacturing industries to maintain product quality and efficiency. Contaminated brass components can affect the production process. |

| Marine | Brass fittings and fixtures on ships and boats need to be clean to prevent corrosion and ensure seaworthiness. Clean brass surfaces also contribute to the aesthetics of marine vessels. |

| Construction | Brass hardware and fixtures in construction projects should be kept clean to maintain the integrity and appearance of buildings. Clean brass surfaces enhance the overall design of structures. |

Methods for cleaning brass surfaces

There are several methods for cleaning brass surfaces, including:

- Using a mild detergent and water to remove dirt and grime

- Polishing brass surfaces with a brass cleaner or polish

- Using a brass brush or cloth to scrub away tarnish

- Applying a protective coating to prevent tarnishing and corrosion

It is important to follow the manufacturer’s recommendations and guidelines when cleaning brass surfaces to avoid damaging the metal.

Conclusion

Maintaining clean brass surfaces is essential in various industries to ensure optimal performance, longevity, and aesthetics of brass components. By regularly cleaning and maintaining brass surfaces, industries can prevent corrosion, improve conductivity, and extend the lifespan of brass products. It is important for businesses to prioritize the cleanliness of brass surfaces to maximize the benefits of using this versatile metal alloy.

Case studies showcasing successful laser cleaning of brass surfaces

Case Study 1: Restoring antique brass fixtures

A historic hotel in downtown New York City was undergoing renovations, and the brass fixtures in the lobby had become tarnished and dull over the years. The hotel’s management wanted to restore the fixtures to their original luster without damaging the intricate designs and details. Laser cleaning was chosen as the method of choice due to its precision and non-invasive nature.

The laser cleaning process was able to remove years of built-up grime and tarnish from the brass fixtures, revealing the intricate details and designs underneath. The hotel’s management was thrilled with the results, and the restored fixtures added a touch of elegance and sophistication to the newly renovated lobby.

Case Study 2: Cleaning brass components in a manufacturing facility

A manufacturing facility that produces brass components for various industries was experiencing issues with contamination on their finished products. Traditional cleaning methods were not effective in removing the contaminants, leading to increased rejection rates and production delays. Laser cleaning was proposed as a solution to the problem.

The laser cleaning process was able to remove the contaminants from the brass components quickly and efficiently, resulting in a significant reduction in rejection rates and production delays. The manufacturing facility was able to meet their production targets and improve the quality of their finished products, leading to increased customer satisfaction and repeat business.

Case Study 3: Restoring brass sculptures in a museum

A prestigious museum in Europe was home to a collection of brass sculptures that had become tarnished and dirty over the years. Traditional cleaning methods were not suitable for the delicate nature of the sculptures, and the museum’s curators were concerned about causing damage to the intricate details and designs. Laser cleaning was chosen as a safe and effective method for restoring the sculptures.

The laser cleaning process was able to remove the tarnish and dirt from the brass sculptures without causing any damage to the delicate details and designs. The museum’s curators were impressed with the results, and the restored sculptures were once again able to be displayed in all their glory. Visitors to the museum were able to appreciate the beauty and craftsmanship of the sculptures thanks to the laser cleaning process.

Conclusion

These case studies showcase the successful use of laser cleaning for restoring brass surfaces in a variety of applications. Whether it’s restoring antique fixtures, cleaning manufacturing components, or preserving museum sculptures, laser cleaning offers a fast, efficient, and non-invasive method for bringing brass surfaces back to their original condition. The precision and effectiveness of laser cleaning make it an ideal choice for anyone looking to restore the beauty and luster of brass surfaces without causing damage or harm.

- Sure! Here are some questions related to the topic of product configurators and their impact on sales: - 18 October 2025

- Why choose Software House Poland for your next project? - 25 September 2025

- The basics of Mobile app development - 21 August 2025

Recent Comments