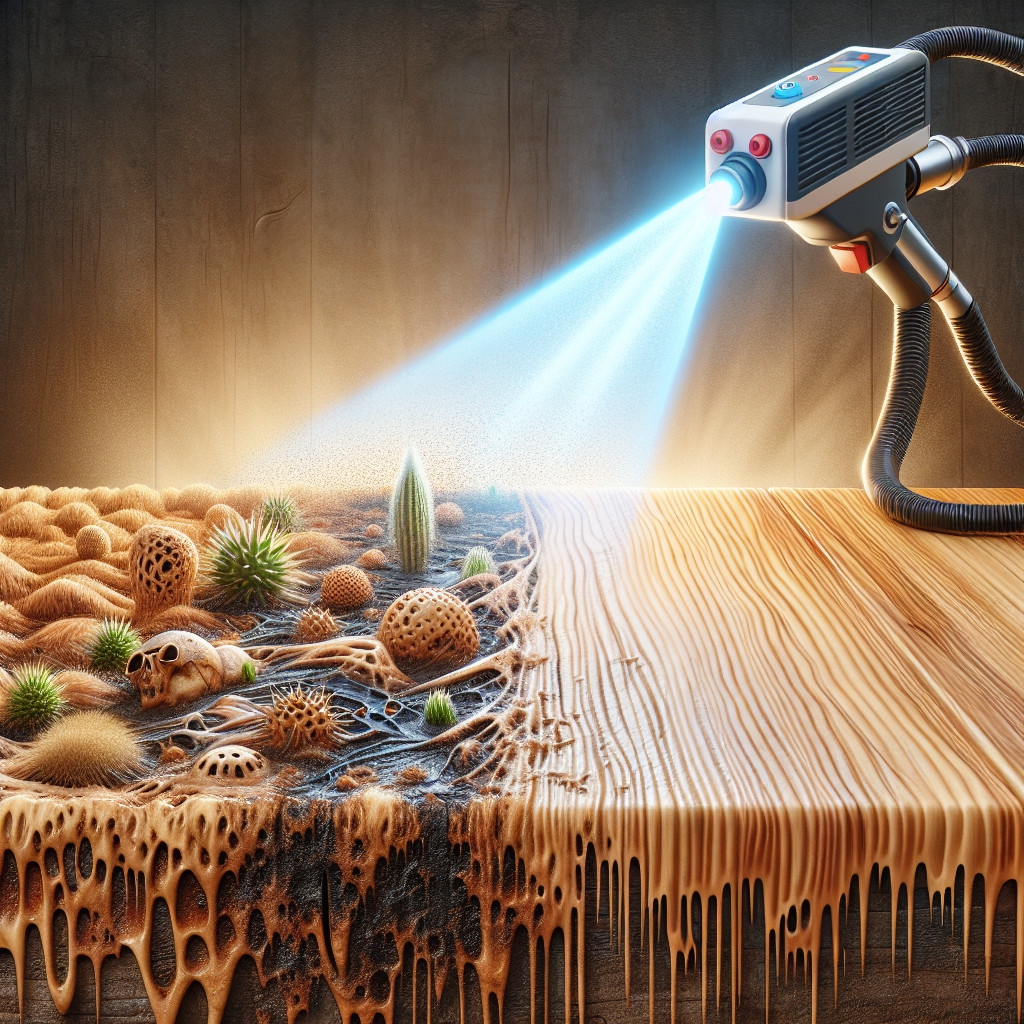

Laser cleaning for removing contaminants from wood surfaces

- Benefits of using laser cleaning for wood surfaces

- Types of contaminants that can be removed with laser cleaning

- Safety precautions when using laser cleaning on wood surfaces

- Case studies of successful laser cleaning projects on wood surfaces

- Advancements in laser cleaning technology for wood surfaces

- The role of laser cleaning in preserving historical wooden artifacts

- Types of contaminants that can be removed with laser cleaning

- Environmental impact of laser cleaning compared to chemical cleaning

Benefits of using laser cleaning for wood surfaces

Wood surfaces are a popular choice for many applications, from furniture to flooring. However, over time, these surfaces can become dirty, stained, or damaged. Traditional cleaning methods such as sanding or chemical treatments can be time-consuming, labor-intensive, and potentially harmful to the environment. Laser cleaning offers a modern and efficient alternative that provides numerous benefits for wood surfaces.

Here are some of the key :

1. Non-contact cleaning: Laser cleaning is a non-contact process, which means that there is no physical contact between the cleaning equipment and the wood surface. This eliminates the risk of damage to the wood and ensures a gentle and precise cleaning process.

2. Environmentally friendly: Laser cleaning does not require the use of chemicals or solvents, making it an environmentally friendly cleaning option. This reduces the risk of harmful chemicals leaching into the environment and minimizes the impact on air and water quality.

3. Efficient and time-saving: Laser cleaning is a fast and efficient process that can remove dirt, grime, and stains from wood surfaces quickly and effectively. This can save time and labor costs compared to traditional cleaning methods.

4. Versatile: Laser cleaning can be used on a wide range of wood surfaces, including furniture, flooring, and decorative items. It can remove paint, varnish, rust, and other contaminants without damaging the underlying wood.

5. Precision cleaning: Laser cleaning allows for precise control over the cleaning process, making it ideal for delicate or intricate wood surfaces. It can remove contaminants from hard-to-reach areas and restore the natural beauty of the wood.

In conclusion, laser cleaning offers numerous benefits for wood surfaces, including non-contact cleaning, environmental friendliness, efficiency, versatility, and precision. By using laser cleaning technology, you can effectively clean and restore wood surfaces without the need for harsh chemicals or labor-intensive methods.

#laser #cleaning #wood #surfaces

Keywords: laser cleaning, wood surfaces, benefits, non-contact cleaning, environmentally friendly, efficient, versatile, precision cleaning

Long-tail phrases: , advantages of laser cleaning for wood, laser cleaning for wood surfaces benefits.

Types of contaminants that can be removed with laser cleaning

1. Rust: Laser cleaning can effectively remove rust from metal surfaces, restoring them to their original condition.

2. Paint: Whether it’s old paint on a wall or graffiti on a building, laser cleaning can easily remove paint without damaging the underlying surface.

3. Grease and oil: Laser cleaning is also effective at removing grease and oil from machinery and equipment, helping to improve their performance and longevity.

4. Oxidation: Oxidation can cause surfaces to become dull and discolored, but laser cleaning can quickly and efficiently remove this layer of oxidation, restoring the surface to its original shine.

5. Mold and mildew: Laser cleaning can be used to remove mold and mildew from surfaces, helping to improve indoor air quality and prevent health issues.

6. Adhesives: Whether it’s tape residue or glue from stickers, laser cleaning can easily remove adhesives without damaging the surface underneath.

7. Dirt and grime: Laser cleaning is also effective at removing dirt and grime from surfaces, leaving them clean and looking like new.

In conclusion, laser cleaning is a versatile and efficient method for removing a wide range of contaminants from various surfaces. Whether it’s rust, paint, grease, or mold, laser cleaning can help restore surfaces to their original condition without causing any damage.

#laser #cleaning #contaminants #rust #paint #grease #oil #oxidation #mold #mildew #adhesives #dirt #grime

słowa kluczowe: laser cleaning, contaminants, rust, paint, grease, oil, oxidation, mold, mildew, adhesives, dirt, grime.

frazy kluczowe: laser cleaning for rust removal, paint removal with laser cleaning, benefits of laser cleaning, laser cleaning applications, laser cleaning technology advancements.

Safety precautions when using laser cleaning on wood surfaces

- Wear protective gear: When using laser cleaning equipment, it is essential to wear appropriate protective gear, such as safety goggles, gloves, and a face shield. This will help protect your eyes, skin, and lungs from potential hazards.

- Ensure proper ventilation: Laser cleaning can produce fumes and smoke that may be harmful if inhaled. Make sure to work in a well-ventilated area or use a fume extraction system to remove any airborne contaminants.

- Follow manufacturer’s instructions: Always read and follow the manufacturer’s instructions for the laser cleaning equipment. This will help ensure that you are using the technology safely and effectively.

- Keep a safe distance: When operating the laser cleaning equipment, make sure to maintain a safe distance from the wood surface being cleaned. This will help prevent accidental burns or injuries.

- Inspect the wood surface: Before using laser cleaning technology, inspect the wood surface for any potential hazards, such as flammable materials or coatings that may react to the laser. Take appropriate precautions to avoid accidents.

- Monitor the cleaning process: Keep a close eye on the cleaning process to ensure that it is proceeding smoothly and without any issues. If you notice any abnormalities, stop the process immediately and address the problem.

By following these safety precautions, you can effectively use laser cleaning technology on wood surfaces without putting yourself or others at risk. Remember to always prioritize safety when working with powerful equipment like lasers.

#woodsurfaces #safetytips #laser #cleaning #protectivegear #ventilation #manufacturerinstructions #safedistance #inspections #monitoring

frazy kluczowe:

– Safety precautions for laser cleaning on wood surfaces

– Laser cleaning safety tips

– Wood surface cleaning with lasers

– How to safely use laser cleaning technology on wood surfaces

– Preventing accidents when using laser cleaning on wood surfaces

Case studies of successful laser cleaning projects on wood surfaces

Here are some examples of successful laser cleaning projects on wood surfaces:

1. Restoration of antique wooden furniture: A furniture restoration company used laser cleaning technology to remove years of dirt and grime from a set of antique wooden furniture. The laser was able to clean the intricate carvings and details on the furniture without damaging the wood.

2. Cleaning of wooden sculptures: An art gallery used laser cleaning to restore several wooden sculptures that had been damaged by environmental pollutants. The laser was able to remove the dirt and grime from the sculptures, revealing the original beauty of the wood.

3. Removal of paint from wooden beams: A construction company used laser cleaning to remove old paint from wooden beams in a historic building. The laser was able to strip away the paint without damaging the wood, allowing the beams to be restored to their original condition.

4. Cleaning of wooden floors: A homeowner used laser cleaning technology to remove stains and dirt from their wooden floors. The laser was able to clean the floors without the need for harsh chemicals or abrasive scrubbing, leaving the wood looking like new.

Overall, these case studies demonstrate the versatility and effectiveness of laser cleaning technology on wood surfaces. Whether it’s restoring antique furniture, cleaning wooden sculptures, or removing paint from wooden beams, laser cleaning offers a safe and efficient solution for cleaning and restoring wood surfaces.

#laser #cleaning #wood #surfaces #restoration #technology

frazy kluczowe:

– Successful laser cleaning projects on wood surfaces

– Laser cleaning technology on wood

– Case studies of laser cleaning on wood surfaces

– Wood surface restoration with laser cleaning

– Laser cleaning for wooden furniture restoration

Advancements in laser cleaning technology for wood surfaces

Benefits of laser cleaning technology for wood surfaces:

– Non-contact cleaning process

– Environmentally friendly

– Precise and controlled cleaning

– No damage to the wood surface

– No residue left behind

Recent :

1. Improved laser beam quality: Advances in laser technology have led to the development of lasers with higher beam quality, allowing for more precise and efficient cleaning of wood surfaces.

2. Enhanced automation: Automation features have been integrated into laser cleaning systems, allowing for faster and more consistent cleaning of wood surfaces.

3. Customizable settings: Laser cleaning systems now offer customizable settings to adjust the intensity and focus of the laser beam for different types of wood surfaces.

Overall, laser cleaning technology has revolutionized the way wood surfaces are treated, offering a more efficient and environmentally friendly alternative to traditional cleaning methods. With continued advancements in this technology, we can expect to see even more benefits and applications in the future.

#laser #cleaning #technology #wood #surfaces

Keywords: laser cleaning, wood surfaces, advancements, technology, environmentally friendly

Long-tail phrases: laser cleaning technology for wood surfaces, non-contact cleaning process, environmentally friendly solution, precise and controlled cleaning, advancements in laser technology.

The role of laser cleaning in preserving historical wooden artifacts

One innovative method that has been gaining popularity in the preservation of historical wooden artifacts is laser cleaning. This technology uses a focused beam of light to remove dirt, grime, and other contaminants from the surface of the artifact without causing damage to the underlying wood. Laser cleaning is a non-invasive and precise method that can effectively restore the original appearance of the artifact while preserving its integrity.

🔹 Laser cleaning is particularly useful for delicate wooden artifacts that cannot withstand traditional cleaning methods such as abrasive techniques or chemical treatments.

🔹 The controlled nature of laser cleaning allows conservators to target specific areas of the artifact, ensuring that only the surface contaminants are removed while leaving the underlying wood untouched.

🔹 Laser cleaning is also a more environmentally friendly option compared to traditional cleaning methods, as it does not require the use of harsh chemicals or solvents that can be harmful to both the artifact and the environment.

🔹 In addition to cleaning, laser technology can also be used for the restoration of wooden artifacts by removing layers of paint or varnish that may have been added over the years, revealing the original wood underneath.

Overall, laser cleaning plays a crucial role in the preservation of historical wooden artifacts by providing a gentle and effective cleaning method that helps to maintain the integrity and beauty of these valuable pieces of history.

#preservation #woodenartifacts #laser cleaning #historicalartifacts

frazy kluczowe:

– Innovative preservation method for wooden artifacts

– Non-invasive cleaning technology for delicate artifacts

– Environmentally friendly restoration option for historical pieces

Types of contaminants that can be removed with laser cleaning

1. Rust: Laser cleaning can effectively remove rust from metal surfaces, restoring them to their original condition.

2. Paint: Whether it’s old paint on a wall or graffiti on a building, laser cleaning can easily remove paint without damaging the underlying surface.

3. Grease and oil: Laser cleaning is also great for removing grease and oil stains from machinery and equipment.

4. Oxidation: Oxidation can cause surfaces to become dull and discolored, but laser cleaning can quickly restore their shine.

5. Mold and mildew: Laser cleaning can effectively remove mold and mildew from surfaces, making them safe and clean.

6. Residue from adhesives: Whether it’s tape residue or glue, laser cleaning can easily remove any sticky residue from surfaces.

7. Carbon deposits: Laser cleaning is also effective at removing carbon deposits from surfaces, such as engine parts or exhaust systems.

8. Dirt and grime: Laser cleaning can quickly and efficiently remove dirt and grime from surfaces, leaving them looking like new.

In conclusion, laser cleaning is a versatile and efficient method for removing a wide range of contaminants from various surfaces. Whether it’s rust, paint, grease, or mold, laser cleaning can effectively clean and restore surfaces to their original condition.

#laser #cleaning #contaminants #rust #paint #grease #oil #oxidation #mold #mildew #adhesives #carbon #dirt #grime

słowa kluczowe: laser cleaning, contaminants, rust, paint, grease, oil, oxidation, mold, mildew, adhesives, carbon, dirt, grime.

frazy kluczowe: laser cleaning for rust removal, paint removal with laser cleaning, laser cleaning for grease and oil stains, laser cleaning for mold and mildew, laser cleaning for adhesive residue, laser cleaning for carbon deposits, laser cleaning for dirt and grime.

Environmental impact of laser cleaning compared to chemical cleaning

Laser Cleaning

Laser cleaning is a non-contact method that uses a high-energy laser beam to remove contaminants from surfaces. The laser beam vaporizes the contaminants, leaving behind a clean surface. One of the main advantages of laser cleaning is that it does not require the use of chemicals, making it an environmentally friendly option.

Another advantage of laser cleaning is that it is a dry process, which means that there is no need for water or other cleaning agents. This reduces the amount of waste generated during the cleaning process. Additionally, laser cleaning is a precise method that can target specific areas without affecting the surrounding surface.

Chemical Cleaning

Chemical cleaning, on the other hand, involves the use of cleaning agents such as solvents, acids, and alkalis to remove contaminants from surfaces. While chemical cleaning is effective, it can have a negative impact on the environment. The use of chemicals can lead to pollution of water sources and soil, as well as harm to wildlife.

Chemical cleaning also generates waste in the form of used cleaning agents and contaminated materials. Proper disposal of these wastes is essential to prevent further environmental damage. In addition, the production and transportation of cleaning agents contribute to carbon emissions and other pollutants.

Comparison

When comparing the environmental impact of laser cleaning and chemical cleaning, it is clear that laser cleaning is the more environmentally friendly option. Laser cleaning does not require the use of chemicals, reducing the risk of pollution and harm to the environment. Additionally, laser cleaning generates less waste and does not contribute to carbon emissions.

While chemical cleaning is still widely used, there is a growing trend towards more sustainable cleaning methods such as laser cleaning. Companies and industries are increasingly recognizing the importance of reducing their environmental impact and are turning to cleaner alternatives.

Conclusion

In conclusion, the environmental impact of laser cleaning is significantly lower compared to chemical cleaning. Laser cleaning is a cleaner, more sustainable option that can help protect the environment and reduce pollution. As technology continues to advance, we can expect to see more widespread adoption of laser cleaning in various industries.

- environmental impact

- laser cleaning

- chemical cleaning

- sustainable cleaning methods

- pollution prevention

- reducing carbon emissions

- protecting water sources

- minimizing waste generation

- preserving wildlife habitats

#environment #cleaning #sustainability #pollution #laser #chemical #waste #carbonemissions #wildlife #technology

- Sure! Here are some questions related to the topic of product configurators and their impact on sales: - 18 October 2025

- Why choose Software House Poland for your next project? - 25 September 2025

- The basics of Mobile app development - 21 August 2025

Recent Comments